A broken commercial overhead door is never just an inconvenience. It’s a direct hit to your operations, your security, and ultimately, your bottom line. When a door goes down, it can stop shipments, leave valuable assets exposed, and create significant safety hazards under OSHA guidelines.

This guide is your practical playbook for navigating these situations, minimizing costly downtime, and making smart, data-informed decisions about commercial overhead door repair.

Responding to Commercial Door Failures

Whether you’re running a business in North Texas or Southern Oklahoma, a malfunctioning commercial door brings your day to a grinding halt. For a warehouse or logistics center, a single inoperable dock door creates a bottleneck that can cost thousands in delayed shipments. It’s a critical business problem.

In fact, industry reports show that unscheduled equipment downtime can cost manufacturing facilities up to $50 billion annually, with failed doors being a major contributor.

This guide gets straight to the point, offering actionable advice for facility managers and business owners. We’ll cover how to safely assess common issues—from a door stuck open to one making a gut-wrenching grinding noise—and help you understand the difference between a simple fix and a crisis that needs an expert now.

Key Risks of a Failed Commercial Door

When a commercial door fails, the fallout extends far beyond a stuck piece of metal. Understanding these risks drives home the need for a rapid and professional repair strategy.

- Operational Disruption: A stuck door directly impacts your flow of goods and services. A 2022 survey found that 82% of companies experienced at least one unplanned downtime event over the past three years, with an average cost of $260,000 per hour.

- Security Breaches: An unsecured opening is an invitation for theft and unauthorized entry. Your inventory, equipment, and sensitive data are suddenly vulnerable.

- Safety Hazards: A failing door, especially one with a snapped spring or frayed cable, is a massive liability. Heavy, unpredictable doors are a serious threat to your team, and OSHA regulations (Standard 1910.212) require employers to protect workers from such hazards.

- Regulatory Compliance: Many commercial doors, particularly automated ones, must meet specific safety codes like UL 325. A non-compliant door or a shoddy repair can lead to fines and legal headaches.

Let's be clear: door failures aren't just mechanical problems; they are business problems. Depending on your industry, the average cost of downtime can run anywhere from hundreds to thousands of dollars per hour.

This is exactly why having a clear plan for commercial overhead door repair isn't just a good idea—it's a critical part of your risk management strategy.

To get a better sense of the real-world financial impact, you can check out these surprising stats about commercial door failures that every property owner should know. Having this background will help you make the most of the detailed steps that follow.

Understanding Your Commercial Door System

Before you can troubleshoot a problem, you need to know what you’re looking at. A commercial door is industrial machinery, engineered to handle incredible weight and relentless use. Its scale and power make understanding its basic anatomy critical for safety and for accurately describing the problem to a repair technician.

These doors are a serious investment and a central part of a building’s infrastructure. That’s why the commercial overhead doors market is valued at roughly USD 3.01 billion in 2024 and is expected to hit USD 4.59 billion by 2029. This growth is fueled by industrial expansion and the booming e-commerce logistics sector in hubs across Texas and Oklahoma. You can read the full research on these market trends to get a sense of just how vital these systems are.

Core Components Under Stress

A few key parts do the heavy lifting, which means they’re also the parts that take the most abuse. Knowing what they do can help you quickly narrow down the source of a problem.

- Torsion Springs: These are the true workhorses of the system. Wound under extreme tension, they counterbalance the door's massive weight, allowing the operator to lift it without burning out. A snapped spring is not only a common failure but also one of the most dangerous jobs in commercial overhead door repair.

- Steel Lift Cables: These cables work in tandem with the springs. They connect to the bottom corners of the door and wrap around drums as it opens, doing the actual lifting. A frayed or snapped cable is a critical failure that requires immediate attention.

- Rollers and Tracks: The rollers guide the door within the tracks. On a commercial door, these are heavy-duty steel components built for thousands of cycles. A bent track or a seized roller can cause the door to jam, shudder, or come completely off its tracks.

Critical Differences from Residential Doors

It's easy to underestimate the differences between commercial and residential doors, but that's what makes specialized service so essential. Commercial doors use a much thicker gauge of steel for panels, tracks, and hardware, making them tougher but also significantly heavier.

The biggest difference comes down to mandatory safety features. Under UL 325 standards, all commercial door operators manufactured since 1993 must have monitored safety devices, like photo-eye sensors or a reversing sensing edge. These aren't optional; they are a legal requirement under federal law to prevent entrapment and protect your personnel.

This heavy-duty construction and required safety technology set your business’s door apart. When you call a pro, being able to say "I think the reversing edge is malfunctioning" instead of just "the door won't close" helps the technician arrive with the right parts and a solid game plan. This knowledge also helps you understand a repair quote and why certain jobs, especially those involving springs, are strictly for professionals.

A Practical Diagnostic Checklist for Your Team

When a commercial door goes down, every minute of downtime hurts your bottom line. Before you call for commercial overhead door repair, a quick, safe diagnosis on-site can often pinpoint the problem. Sometimes, it's a five-minute fix your own team can handle, saving you a service call and getting you back up and running fast. Arming your facility staff with this basic checklist is a smart first move.

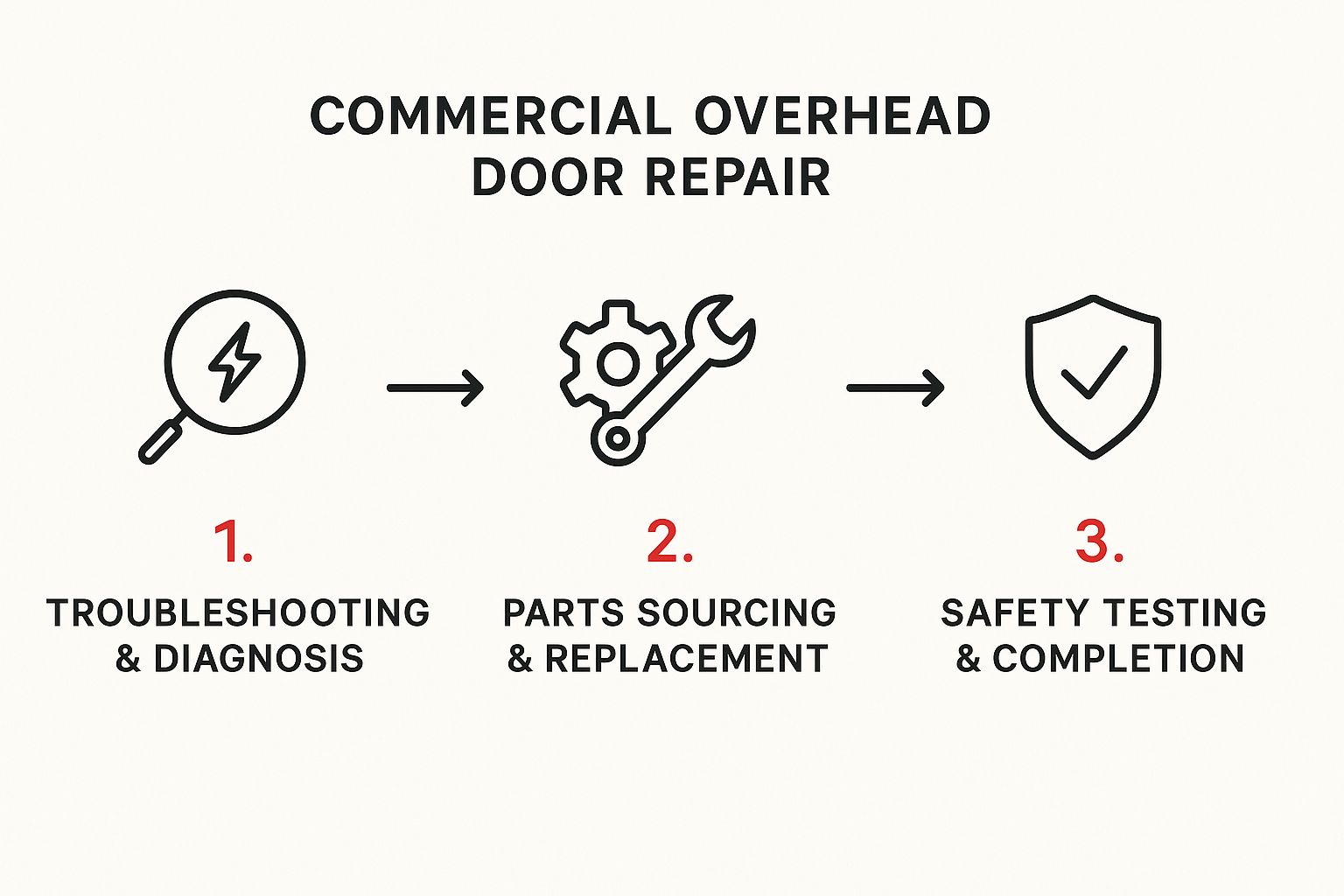

This workflow breaks down how a professional repair unfolds, starting with that crucial first look and ending with comprehensive safety checks.

As you can see, a proper repair isn't just about replacing a broken part. It's a methodical process that puts accurate troubleshooting and safety at the forefront.

Door Is Completely Unresponsive

This is one of the most common calls we get, and it’s often the easiest to solve. Before assuming the worst (like a dead motor), have your team run through these power-related basics.

- Check the Power Source: It sounds too simple, but is the operator plugged in securely? Next, plug another device into the outlet to confirm it has power. If not, check your circuit breaker panel for a tripped breaker.

- Inspect the Disconnect: Most commercial operators have an emergency disconnect chain or switch. If it has been pulled, it cuts power to the motor. Ensure it's in the standard operating position.

- Test All Controls: Try every way you have to open the door—the main wall button, remote clickers, and keypads. If one works but another doesn't, you've isolated the problem to the control device, not the door operator itself. For a deeper dive into operator issues, you can find more in our guides to commercial door systems.

Door Moves Erratically or Reverses on Its Own

If the door starts to close and then suddenly stops, shudders, or reverses, something is likely triggering its UL 325-mandated safety system or physically blocking its path.

CRITICAL SAFETY WARNING

Your team should never attempt to adjust, repair, or touch high-tension components. This means staying clear of the large torsion springs above the door and the steel lift cables on the sides. These parts are under extreme load and can cause catastrophic failure, leading to severe injury or death. This work is exclusively for trained professionals.

Here’s what your team can check safely:

- Look at the Photo-Eye Sensors: Near the bottom of the tracks, you'll find a pair of small sensors. They must be perfectly aligned to "see" each other. Check the small LED lights on them—they should be solid (usually one green, one amber/red). If a light is blinking, they're either blocked or misaligned. Wipe the lenses clean and gently adjust one sensor until both lights are solid.

- Clear the Door's Path: Walk the entire opening and look for anything in the way. A misplaced pallet, a broom handle, or debris in the tracks can be enough to make the door think it's hit something and reverse.

- Eyeball the Tracks: Do a quick visual inspection of the vertical and horizontal tracks for major dents or bent sections. Do not try to hammer anything back into place. Significant track damage requires professional alignment and is a job for a pro with the right tools for commercial door repair services.

Door Is Off Its Tracks or Making Loud, Ugly Noises

A door that has jumped its track is a massive safety hazard. The same goes for any sudden, loud grinding, popping, or screeching sounds—these are red flags for serious mechanical failure.

When you see or hear these symptoms, the checklist is short and non-negotiable:

- Stop everything. Do not attempt to operate the door again.

- Secure the area. Use caution tape or cones to block off access so no one is in the hazard zone.

- Call a professional immediately. These are signs of a critical failure, like a snapped cable, broken rollers, or failing gears in the operator.

Running through these quick diagnostics helps sort simple fixes from serious problems. When you do make a service call, you’ll be able to give the technician specific details, which helps us diagnose the issue faster and arrive with the right parts. For more on this, check out these common questions about commercial door repair.

Commercial Overhead Door Troubleshooting Guide

When your door acts up, it's tough to know whether you're facing a quick fix or a serious hazard. This table is a quick reference to help you identify what's going on based on the symptoms and decide on the safest next step.

| Symptom | Potential Cause | Safe to Check (DIY) | When to Call a Pro |

|---|---|---|---|

| Door won't move at all; no sound from motor. | Power issue, disengaged motor, faulty controller. | Check power outlet, circuit breaker, and emergency disconnect. Test all remotes/buttons. | Immediately, if all power checks are fine. |

| Door closes partway, then reverses. | Blocked or misaligned photo-eye sensors, obstruction in the path. | Clean sensor lenses, check for solid LED lights, and clear any obstructions from the door's path. | If sensors are aligned and the path is clear but the problem persists. |

| Loud grinding, popping, or screeching noises. | Broken spring, snapped cable, worn rollers, failing operator gears. | Nothing. Do not operate the door. | Immediately. These are signs of critical component failure. |

| Door looks crooked or is off its track. | Snapped lift cable, broken roller, impact damage to the track. | Nothing. This is an extremely dangerous situation. | Immediately. The door is unstable and could fall. |

| Remote control or keypad doesn't work. | Dead batteries, signal interference, needs reprogramming. | Replace batteries in the remote/keypad. Try operating the door from the wall switch. | If new batteries don't work and the wall switch does. |

This guide is designed to empower you to handle the small stuff safely while recognizing the big problems that require an expert. When in doubt, always prioritize safety and call a certified technician.

Smart Maintenance to Prevent Costly Downtime

The best commercial overhead door repair is the one you never have to make. Shifting from a reactive, emergency-fix model to a proactive maintenance mindset is one of the smartest investments a business in Texas or Oklahoma can make. It’s the difference between smooth operations and a business-halting emergency.

A well-maintained door simply breaks down less often. This protects your workflow, security, and bottom line. According to industry data, a preventive maintenance program can reduce equipment breakdowns by up to 70-75%. This is a strategic move that pays for itself.

Building a Practical Maintenance Schedule

The key to preventing surprise breakdowns is a consistent schedule. By breaking down tasks into simple monthly, quarterly, and annual checks, you can spot small problems before they escalate into catastrophic failures. To make this work, it's all about effective scheduling practices for maintenance that ensure nothing gets missed.

Here’s a practical framework for your business:

- Monthly Visual Checks (In-House): Once a month, have a team member take five minutes to visually inspect the door. Are all bolts and hinges tight? Are the cables free of frays? Are photo-eye sensors clean and aligned? Catching these things early is half the battle.

- Quarterly Lubrication and Testing (In-House): Every three months, apply a high-quality, manufacturer-approved lubricant to all moving parts—rollers, hinges, and bearings. This is also the perfect time to test the door’s balance and run a check on the auto-reverse safety features to ensure they're functioning per UL 325 standards.

An ounce of prevention is truly worth a pound of cure. A $15 can of lubricant and 15 minutes of your time each quarter can prevent a multi-thousand-dollar repair bill and days of operational chaos.

The Non-Negotiable Annual Professional Inspection

While in-house checks are crucial, they do not replace the trained eye of a certified technician. An annual professional inspection is essential for the long-term health and safety of your door. Technicians have the diagnostic tools and experience to catch subtle warning signs that are easily missed.

This is more than a quick lube-and-go. A technician will properly check and adjust spring tension—a dangerous job for the untrained—and inspect the motor, electrical connections, and the full suite of safety systems. This expert check-up ensures your door isn't just working, but that it also meets critical OSHA and UL 325 safety standards, protecting you from significant liability.

If you're curious about what a professional service entails, you can learn more by exploring our breakdown of commercial door repair services. Think of it as a small investment for major operational continuity and peace of mind.

How to Vet a Repair Service in Texas and Oklahoma

When your commercial overhead door goes down, it’s not just an inconvenience—it’s a direct hit to your operations. Choosing the right repair service in Texas or Oklahoma is a critical decision. You're not just hiring someone to fix a door; you're entrusting them with a vital piece of your facility's security and workflow. Making a snap judgment can lead to shoddy work, recurring problems, and a whole new set of headaches.

The first step, and it's non-negotiable, is to verify their insurance. Don't just take their word for it. Ask to see a current certificate of liability and workers' compensation. If an uninsured contractor has an accident on your property, that liability can fall squarely on your business.

Beyond the Basics: Essential Questions to Ask

Once you’ve confirmed they’re properly insured, it’s time to dig into their actual qualifications. A reputable company will have no problem answering your questions and providing proof of their expertise.

Here’s what you should be asking:

- Are your technicians IDEA accredited? The Institute of Door Dealer Education and Accreditation (IDEA) is the industry's benchmark for excellence. Accreditation means the technicians have proven their knowledge of safety standards, codes like NFPA 80 (for fire doors), and technical skills.

- What's your experience with our specific door type? Get specific. If you have high-speed doors or heavy-duty rolling steel doors, you need a team that has worked on them extensively. Commercial doors are not a one-size-fits-all game.

- What are your emergency service hours and response times? When a door fails, you need to know how quickly you can get help. A two-hour response time versus a next-day appointment can be the difference between a small hiccup and a major operational shutdown.

You're looking for a long-term partner, not just a one-time fix. The right company understands the demands of a commercial environment, from working around your operating hours to respecting your site's safety protocols.

Demystifying Repair Costs and Estimates

Getting a handle on repair costs is essential for avoiding sticker shock. Before you even make a call, it helps to understand the specialized garage door repair industry and how pricing is structured. Always, and I mean always, get a detailed written estimate before authorizing any work.

That estimate should break everything down clearly: the service call fee, the hourly labor rate, and the itemized cost of any parts needed.

It's also worth noting that market forces can affect what you pay. For instance, in April 2025, major manufacturers like Clopay and Amarr both hiked their prices by around 6% due to material costs and supply chain issues. That increase gets passed down and directly impacts the cost of repair components. You can discover more insights about these market shifts and what they mean for service pricing.

By asking the right questions and insisting on a transparent estimate, you empower yourself to hire a professional you can trust. This diligence pays off in a reliable, safe, and secure commercial door for years to come. If you're curious about how demand in your area stacks up, check out the top U.S. cities with the highest demand for commercial door repair.

Your Top Questions About Commercial Door Repair

When your business depends on a big, heavy overhead door going up and down reliably, problems aren't just an inconvenience—they can shut down your entire operation. Over the years, we've heard just about every question from facility managers and business owners across Texas and Oklahoma. Here are some of the most common ones we get, with straightforward answers to help you make the right call for your facility.

The goal here is to cut through the noise and give you practical advice on safety, keeping your business running, and understanding when to call in a pro.

How Often Should We Get Our Commercial Door Serviced?

Honestly, every single commercial door needs a professional tune-up and inspection at least once a year. Think of it like a vehicle inspection—it catches small problems before they become big, expensive ones.

Now, if your doors are in a high-traffic area like a distribution center, warehouse, or a busy parking garage, you need to bump that up to quarterly service. It might seem like a lot, but it's the best way to prevent unexpected downtime. We've seen firsthand how regular maintenance can cut down on emergency breakdowns by as much as 70%. It’s a small, predictable line item in your budget that saves you from a massive, unexpected repair bill down the road.

A scheduled service call is about more than just lubrication. It’s when a trained technician can spot a fraying cable or a weakening spring before it snaps. That simple check is one of the most important things you can do to stay compliant with OSHA safety standards.

What's the First Thing to Break on These Doors?

Nine times out of ten, it’s the torsion springs. No question about it. These springs are the muscle of the door system, constantly under incredible tension to lift and lower hundreds, sometimes thousands, of pounds.

Every time the door opens and closes, that's one "cycle." Most standard commercial springs are built to last for 10,000 to 25,000 cycles. For a busy loading dock in Dallas or Oklahoma City, you can burn through that lifespan much faster than you’d think. Once a spring breaks, the door is dead in the water—and it becomes incredibly dangerous. This is precisely why those annual inspections are so critical; a technician can assess the health of the springs and warn you before they fail.

Should I Repair a Damaged Panel or Just Replace the Whole Door?

This is a classic cost-benefit question, and the right answer really depends on the situation. I always tell my clients to think about three things:

- How bad is the damage? If a forklift just bumped a single panel and left a dent, that’s almost always a simple panel swap. But if the impact was hard enough to damage multiple panels or bend the actual frame, you’re looking at a structural problem. In that case, replacing the whole door is usually the safer, and often cheaper, long-term solution.

- How old is the door? If your door has been in service for 15-20 years, sinking a bunch of money into major repairs is often a bad investment. Newer doors have come a long way in terms of insulation (R-value), security, and safety features. A new door isn't just a repair; it's an upgrade.

- Can we even find a matching panel? For older doors, manufacturers might have discontinued the model. Finding a perfect match can be a real headache, and a mismatched panel not only looks bad but can also throw off the door's balance and operation. At that point, a full replacement just makes more sense.

When Is It a Real Emergency?

You need to call for emergency service anytime the door's failure creates a real, immediate risk to your people, your property, or your ability to do business.

Pick up the phone for an emergency call right away if:

- The door is stuck wide open, leaving your building completely unsecured.

- You see a snapped spring or a broken cable. This is a major safety hazard.

- The door has come off its tracks. It's unstable and could fall at any moment.

- A vehicle or critical equipment is trapped, bringing your operations to a standstill.

For less urgent issues, like a remote that stopped working but the wall button still operates the door, it’s perfectly fine to schedule a regular service call.

When you're facing any of these issues, you need a partner who gets that time is money. For expert diagnostics and dependable commercial overhead door repair across Texas and Oklahoma, you can trust the certified professionals at Overhead Door Co. of Tex-Oma.

Contact us today for a prompt assessment and get your operations back on track.