That grinding, squeaking noise isn't just an annoyance—it's your garage door signaling a need for preventative maintenance. Properly lubricating your garage door is a critical task that involves cleaning key components and then applying a silicone-based or white lithium grease spray to the hinges, metal rollers, and springs. Performing this maintenance just twice a year can significantly extend the life of your system, ensuring smooth and quiet operation.

Why Regular Lubrication is Critical for Your Garage Door

Regular lubrication is one of the most effective, low-cost maintenance tasks you can perform to extend the lifespan of your garage door. It’s not just about silencing noise; it’s about protecting a complex system of moving parts from premature failure.

For property owners in Texas and Oklahoma, where garage doors face heavy use and dramatic temperature swings, this simple task is even more vital. Proper lubrication reduces the immense strain on the opener motor, quiets the operation, and helps you avoid the cost and inconvenience of an emergency repair call.

The Real Cost of Neglect

Ignoring this task can lead to significant problems. Constant metal-on-metal friction grinds down crucial components, forcing your opener to work harder and dramatically increasing the risk of a sudden breakdown.

Consider this: a typical residential garage door cycles approximately 1,500 times per year. Industry data shows that without proper lubrication, the wear and tear—and the associated noise—can increase by over 30% in just 12 to 18 months. This is especially true for the popular steel and aluminum https://ohdctexoma.com/garage-doors/ common in our region. That friction doesn't just shorten component life; it also increases energy consumption as the system strains to operate.

Key Benefits of Proper Lubrication

A few minutes of preventative maintenance provides a significant return on investment. The key benefits are clear:

- Extended Component Life: Drastically reduces wear on rollers, springs, and hinges, extending their operational lifespan and deferring replacement costs.

- Quieter Operation: Eliminates the grinding and squeaking noises caused by metal-on-metal friction.

- Reduced Strain on the Opener: A well-lubricated door allows the motor to work efficiently, prolonging its life and preventing motor burnout.

- Prevents Costly Repairs: Proactive maintenance helps you avoid unexpected breakdowns and the need for an emergency service call from a garage door repair technician.

Choosing the Right Garage Door Lubricant

Selecting the correct lubricant is the most critical part of this maintenance task. It's tempting to grab a can of standard WD-40 or a tub of automotive axle grease, but this common mistake can cause more harm than good.

These types of products are magnets for the dust and grime prevalent in Texas and Oklahoma. They quickly create a thick, gummy sludge that adheres to moving parts. Instead of reducing friction, this gunk accelerates wear and forces the system to work harder. Professional technicians exclusively use lubricants formulated for garage door systems.

Silicone vs. White Lithium Grease

For garage doors, the choice typically narrows down to two excellent options: a silicone-based spray or white lithium grease. Each serves a specific purpose.

- Silicone-Based Spray: This is the ideal lubricant for most moving parts. It applies as a thin spray, penetrates tight spaces like roller bearings and hinges, and dries to a non-stick film that won't attract dirt.

- White Lithium Grease: This is a more heavy-duty lubricant. It clings to metal and provides a thicker, more durable coating, making it perfect for the high-friction environment of an opener's chain or screw drive.

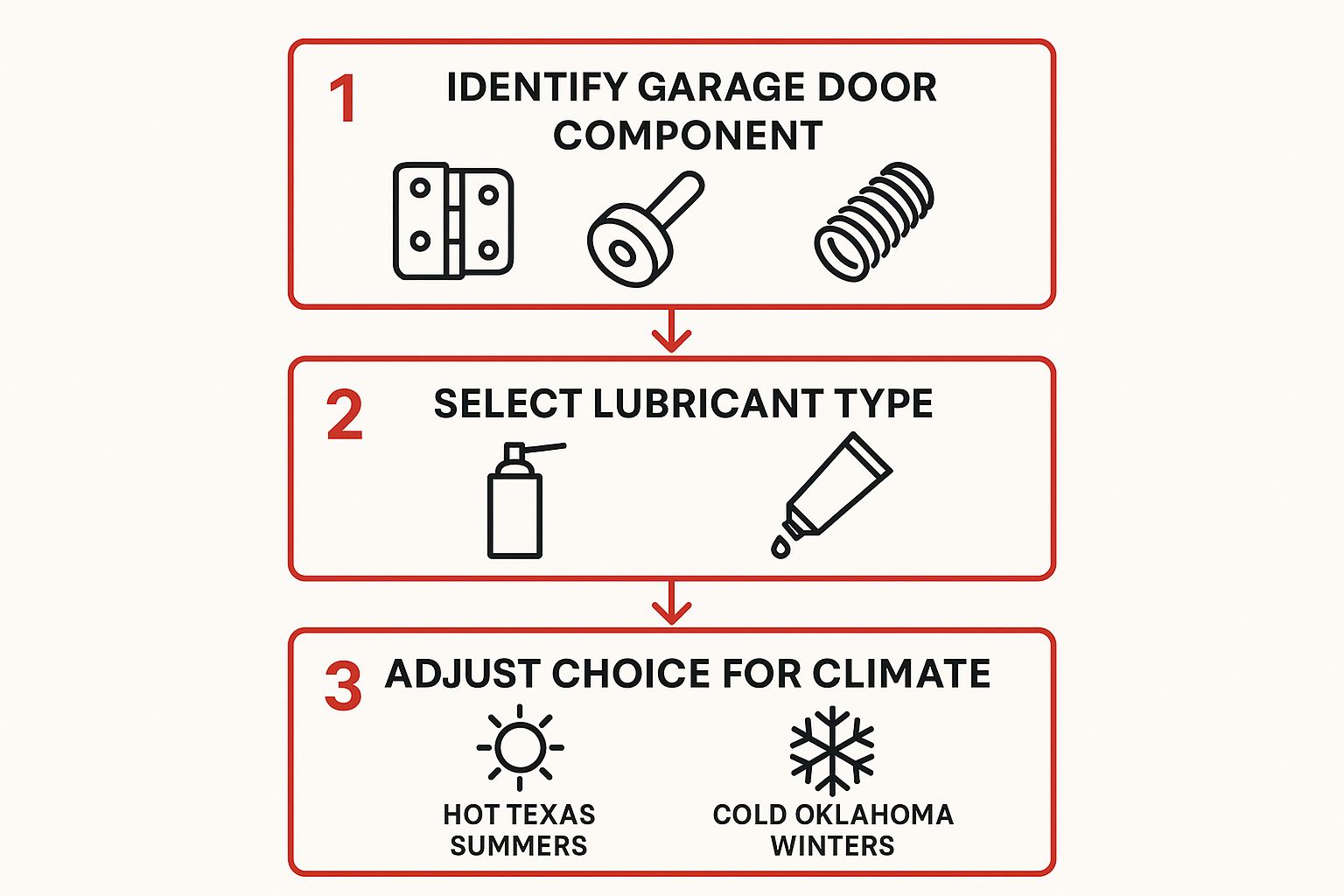

This infographic breaks down how to select the right product for each component, factoring in local climate conditions.

The selection is strategic, designed to match the product's properties to the specific part and the environmental demands it faces.

Using the wrong product can be a costly error. Across the industry, improper lubrication accounts for nearly 15–20% of all service calls, with the average repair bill ranging from $150–$300. Selecting the correct lubricant helps you avoid becoming a statistic and ensures your door operates reliably.

Comparing Lubricants for Your Garage Door

To clarify why some products work while others create problems, this table outlines what professionals use and what to avoid.

| Lubricant Type | Best For | Why It Works (or Doesn't) | Common Mistake |

|---|---|---|---|

| Silicone Spray | Rollers, hinges, springs, tracks | Penetrates tight spaces and dries to a non-stick film that repels dust and moisture. | Using too much; a light, even coat is all that is required. |

| White Lithium Grease | Opener chain, screw drive | Provides a thick, long-lasting coating that adheres well to metal and reduces friction on heavy-load parts. | Applying it to rollers or tracks, where it will attract dirt and gum up the works. |

| WD-40 (Standard) | Not recommended for lubrication | It's a solvent and water displacer, not a long-term lubricant. It attracts dust and can strip away existing grease. | Using it as the primary lubricant instead of for cleaning off old gunk before applying proper lubricant. |

| Grease (General/Axle) | Not recommended | Far too thick and heavy. It creates a sticky paste when mixed with dirt, causing parts to bind and wear out. | Smearing it on the tracks. This is a primary cause of jammed doors. |

Ultimately, having the right product ensures an effective tune-up rather than a frustrating task that fails to solve the underlying issue.

Pro Tip: For the high heat of a Texas summer, a quality silicone spray with a high temperature rating is essential. For the colder, damp Oklahoma winters, white lithium grease provides the drive components a robust barrier against moisture. Having the right garage door accessories on hand makes the entire process more efficient.

The Complete Garage Door Lubrication Process

With the correct lubricant selected, you are ready to begin. This simple maintenance task delivers immediate, noticeable results, transforming a noisy, groaning door into one that operates almost silently. Following a few professional techniques ensures every critical component is addressed for optimal performance.

First, prioritize safety. You must disconnect the power to your automatic garage door opener by unplugging it from the ceiling outlet. Next, pull the red emergency release cord to disengage the opener. This allows you to move the door manually, giving you complete control. As an added precaution, ensure the door is in the down position and secured before working on springs and other high-tension components.

Preparation and Cleaning

The first step in proper lubrication is cleaning. Applying new lubricant over layers of old grime and debris creates an abrasive paste that accelerates wear on the very parts you aim to protect.

Use a clean rag and a vacuum with a brush attachment. Your first target is the garage door tracks. They accumulate a surprising amount of dust, cobwebs, and debris, especially in the Texoma climate. A thorough wipe-down and vacuum provides a clean path for the rollers.

Important Takeaway: Never lubricate the inside of the garage door tracks. The rollers are designed to roll, not slide. Adding grease or oil to the tracks attracts dirt, which can cause the rollers to jam and wear out prematurely.

Applying Lubricant to Key Components

With the tracks clean, you can begin lubricating. A systematic approach, working from bottom to top, ensures no component is missed. Use a piece of cardboard or a rag as a backstop to catch overspray and keep your door and floor clean.

- Hinges: Each door panel has multiple hinges. Apply a quick, direct spray of lubricant to each hinge's pivot point.

- Metal Rollers: Aim the lubricant spray directly into the ball bearings inside the rollers. This is the point of friction. If you have nylon rollers without exposed bearings, they do not require lubrication.

- Bearings: At the top of the track system on each side, you will find bearing plates. These are critical pivot points and require a thorough spray.

- Torsion Springs: This component requires caution. Lightly apply an even coat of lubricant along the entire length of the large springs located above the door. This quiets their operation and helps prevent rust and corrosion.

Lubricating the Opener System

Finally, address the opener itself. The method depends on your system type. For a chain drive, apply a thin layer of white lithium grease directly to the chain. For a screw drive opener, apply the same grease along the full length of the drive screw.

Once lubrication is complete, work the product into the components by manually opening and closing the door several times. This distributes the lubricant evenly into all moving parts. Use a clean cloth to wipe away any excess that has dripped or squeezed out.

This simple maintenance is often overlooked, yet its absence is a leading cause of premature system failure. If you complete these steps and the door continues to operate poorly, it may indicate a more significant issue that requires professional diagnosis.

As a rule of thumb, lubricating all moving parts once or twice a year is the best practice. It is a small investment of time that provides a significant return by extending the life of your entire system and preventing costly breakdowns.

Common Lubrication Mistakes and How to Avoid Them

In garage door maintenance, understanding what not to do is as important as knowing the correct procedure. Many well-intentioned DIY efforts backfire, turning a simple task into a more expensive repair call. A few common mistakes are easily avoidable with the right knowledge.

The most frequent error is over-lubricating. In this case, more is not better. Excess lubricant does not improve performance; it drips onto your vehicle and floor, creating a sticky mess that attracts dust and grime. The goal is a light, even coat—nothing more.

Where Not to Lubricate

Equally important is knowing which parts to leave untouched. Applying lubricant where it doesn’t belong can actively hinder your door's operation. To ensure smooth performance, consider these areas off-limits:

- The Door Tracks: Never spray lubricant inside the metal tracks. This is a non-negotiable rule. Your door's rollers are designed to roll, not slide. Greasing the tracks causes them to slip, leading to premature wear and potentially throwing the door out of alignment.

- Nylon Rollers: If your door is equipped with modern nylon rollers that lack exposed bearings, they are typically self-lubricating. Spraying them is unnecessary and only contributes to a potential mess.

Industry data reveals that a surprising number of garage door failures stem from simple neglect. Some market studies suggest only 40% of homeowners perform any type of routine maintenance. As a result, component failure rates can increase by 25% after just two years of use. You can read more about these market insights to understand why preventative care is so impactful.

The most significant mistake is skipping maintenance altogether. If you've lubricated everything correctly and still hear grinding noises, or if you're not comfortable performing the task, it may be time for a professional tune-up. Scheduling regular maintenance ensures an expert inspects every component, catching small issues before they become major breakdowns.

How to Build a Simple Garage Door Maintenance Routine

View lubrication not as a one-time fix for noise, but as the foundation of a comprehensive maintenance routine that ensures your door operates safely and reliably for years. Establishing this as a regular habit is the most effective way to protect your investment and avoid inconvenient breakdowns.

For most residential and commercial properties in Texas and Oklahoma, a semi-annual schedule is optimal. We advise clients to mark their calendars for spring and fall. A spring tune-up prepares the door for heavy summer use, while a fall application protects it from the cold and damp conditions of winter.

Go Beyond Lubrication with a Complete Checklist

While you have your supplies out, leverage the opportunity to perform a full system health check. Combining lubrication with a few other quick inspections is an efficient way to ensure total system integrity.

Here is a practical checklist:

- Test the Safety Sensors (UL 325 Standard): This is a critical safety check mandated by the UL 325 standard. Place a 2×4 board or a roll of paper towels flat on the ground in the door's path and press the close button. The door must immediately reverse upon contact. If it does not, the sensors require immediate professional attention.

- Check the Hardware: Visually inspect hinges, brackets, and fasteners. The door's vibration can cause nuts and bolts to loosen over time. Use a wrench to tighten any loose hardware.

- Inspect the Weather Stripping: Examine the rubber seal along the bottom of the door. If it is cracked, brittle, or damaged, it is compromising your building's energy efficiency and should be replaced.

For commercial doors in high-cycle environments or residential doors in particularly dusty areas of our region, we recommend increasing this schedule to quarterly. Proactive maintenance is the key to operational continuity and avoiding business disruptions.

This type of proactive care is more important than ever. The garage door market, valued at $6.99 billion in 2022, continues to expand, highlighting how integral these systems are to our homes and businesses. If you're interested, you can explore more about this industry growth and its drivers.

Common Questions About Garage Door Lubrication

Even with a detailed guide, specific questions often arise. We've compiled answers to the most common queries we receive from homeowners and businesses across Texas and Oklahoma.

How Often Should I Lubricate My Door in This Climate?

Here in Texoma, with our intense summer heat and variable winters, preventative maintenance is key. We recommend lubricating your garage door twice a year. A seasonal schedule—once in the spring before heavy summer use, and again in the fall to prepare for winter—is ideal.

For commercial doors with high-cycle usage, a quarterly schedule is necessary to keep pace with the increased wear and tear.

Is It Okay to Use WD-40?

The answer is a definitive no. This is the most common and damaging DIY mistake. Standard WD-40 is a solvent and a water displacer, not a long-term lubricant. It will strip away the existing grease on your door’s components.

Furthermore, its residue attracts dust and grime, creating a gummy paste that worsens friction and can lead to component failure.

Pro Tip: Always use a lubricant specifically designed for this application. A high-quality silicone spray or white lithium grease will create a durable, low-friction surface that repels contaminants and provides lasting protection.

Are There Any Parts I Shouldn't Spray?

Absolutely. Knowing where not to lubricate is as critical as knowing where to.

The primary "no-spray zone" is the inside of the garage door tracks. Rollers are designed to roll freely, not slide in a greasy channel. Lubricating the tracks causes them to slip and grind, leading to excessive wear and potential door misalignment.

Additionally, inspect your rollers. Many modern doors feature nylon rollers with sealed bearings that are designed to be self-lubricating and do not require any additional spray.

At Overhead Door Co. of Tex-Oma, we understand that proactive maintenance is the key to a long-lasting, reliable garage door system. If you encounter an issue or prefer a professional inspection, our expert team is ready to assist. Reach out for expert service or to learn about our preventative maintenance plans at https://ohdctexoma.com.