Your garage door might weigh hundreds of pounds, but a properly calibrated spring system makes it feel light enough to lift with one hand. That feeling of weightlessness isn’t magic; it’s the result of perfectly calibrated tension. This precise balance is the heart of your door’s operation and, more importantly, its safety. Without it, the system is just dangerous dead weight. For homeowners and business operators in Texas and Oklahoma, understanding this principle is key to a reliable and secure property.

Why Getting the Spring Tension Right Is a Non-Negotiable

Think of your garage door’s springs as the muscle of the whole operation. People often credit the opener for doing the work, but it’s really just the guide. The springs are what do the actual heavy lifting. They are wound or stretched under immense force to store mechanical energy, which is then used to perfectly counterbalance the door’s weight.

When that tension is dialed in correctly, the door is essentially weightless. This allows your opener motor to gently guide it along the tracks instead of straining to lift a massive load. That means less wear and tear, a longer lifespan for your motor, and fewer expensive breakdowns. This is especially true for our business clients in Texas and Oklahoma, where heavy-duty commercial doors absolutely depend on proper tension for daily operations and to meet OSHA safety standards for the workplace.

Torsion vs. Extension Springs: A Quick Primer

You’ll typically find one of two spring systems on a garage door, and they each handle tension in their own way:

- Torsion Springs: These are the large, tightly wound springs on a metal bar directly above the garage door opening. They work by twisting (creating torque) to lift the door’s weight. Due to their durability and controlled movement, torsion springs are the standard for most modern homes and virtually all commercial properties.

- Extension Springs: You’ll find these running alongside the horizontal tracks on each side of the door. They work like giant, powerful rubber bands, stretching out as the door closes to store energy and contracting to help lift it.

While they look and function differently, the end goal is always the same: achieving a perfect state of balance where the springs support the door’s entire weight.

Red Flags: How to Spot Improper Spring Tension

An imbalanced door isn’t just an inconvenience that wears out parts faster—it’s a serious safety risk. If the tension is too low, the door can come crashing down without warning. If it’s too high, it can fly open uncontrollably, posing a threat to people, pets, or property.

A key reason tension fails is simply age. A standard garage door torsion spring is rated for about 10,000 cycles—one cycle is a full open and close. For the average family, that’s about 7 to 10 years of use before the steel starts to fatigue and can no longer hold the proper tension. You can learn more about the risks of weakened garage door springs and why they fail over time.

Catching the signs early is critical. The easiest and most practical way to check is to perform a balance test. Disconnect the door from the opener and lift it by hand until it’s about halfway open. If it stays put, you’re in good shape. But if it starts to drift down or tries to shoot upward, you have a tension problem that needs immediate professional attention. We see it all the time: customers call us for a burned-out opener, only to learn the real culprit was a motor that spent years fighting an imbalanced door.

To help you troubleshoot, here’s a quick chart to identify what might be going on with your door.

Quick Diagnostic Chart for Spring Tension Issues

Use this table to quickly identify common symptoms of improper garage door spring tension.

| Symptom | Likely Cause (Tension Level) | Immediate Action |

|---|---|---|

| Door feels very heavy to lift manually. | Too Little Tension: The springs aren’t providing enough lift assistance. | Stop use immediately. The door could fall. Schedule a professional adjustment. |

| Door slams shut when closing. | Too Little Tension: Gravity is overpowering the weak springs. | Dangerously unsafe. Do not park or stand under the door. Call a technician. |

| Door won’t stay open when disconnected from the opener. | Too Little Tension: The springs can’t counterbalance the door’s weight. | Cease using the door. Professional adjustment is required to prevent a free-fall. |

| Door is difficult to pull down. | Too Much Tension: The springs are pulling up too hard. | Avoid forcing the door. This puts stress on panels and the opener. Seek adjustment. |

| Door shoots up when opened manually. | Too Much Tension: The springs are overpowered and can cause uncontrolled movement. | Stand clear of the door’s path. Call for a professional to safely reduce the tension. |

Remember, this chart is for diagnostic purposes only. Any adjustments, especially to torsion springs, carry significant risk and are best left to trained professionals.

The Unmistakable Dangers of DIY Spring Adjustment

Before you grab a wrench, let’s talk about the physics involved. A garage door torsion spring isn’t just a simple coil of metal; it’s a powerhouse of stored mechanical energy. When it’s properly wound, it holds an incredible amount of force in check—enough to lift a door weighing several hundred pounds.

Attempting to adjust that spring isn’t like tightening a loose bolt. You’re handling a device that, if it fails, can unleash that energy in a split second. We’re talking about catastrophic failure.

The spring can snap and whip around like a metal bullwhip, or it can shatter and spray steel shrapnel across your garage. At the same time, the door loses its counterbalance and can come crashing down with enough force to crush anything—or anyone—in its path. This isn’t a scare tactic; it’s a grim reality based on industry accident data.

Understanding the Real-World Risks

For property owners in Texas and Oklahoma, the stakes are even higher. Our doors are often heavy and insulated to deal with the weather, which means the springs are under even greater tension. A crucial part of any professional job is proper hazard identification—something most DIY videos completely gloss over.

The numbers don’t lie. According to the U.S. Consumer Product Safety Commission (CPSC), garage doors are responsible for thousands of injuries each year. A significant portion of these are severe lacerations, fractures, and crushing injuries directly caused by failed or improperly handled spring systems.

Why Professionals Use Specialized Tools

One of the most common and dangerous mistakes we see is someone trying to use a screwdriver or a piece of rebar to wind or unwind a torsion spring. This is a recipe for disaster. Professional technicians rely on winding bars—solid steel rods designed to fit perfectly and securely into the spring’s winding cone.

Here’s the hard truth: A screwdriver will bend or snap under the torque. When it does, it becomes a projectile. If the bar slips out of the hole—which is very likely—the spring will unwind violently, sending that tool flying with enough force to break bones or shatter a car window.

It’s not just about having the right tool; it’s about having the experience to use it. A pro knows exactly how to lock the door in place, release the tension methodically, and apply the precise number of quarter-turns required for your door’s specific weight and height. When you weigh the potential savings of a DIY job against the cost of an emergency room visit or thousands in property damage, the choice is clear. For any potential issues, our garage door spring repair team is ready to help safely.

How Professionals Adjust Torsion Spring Tension

Adjusting a torsion spring isn’t just about muscle; it’s a methodical process that demands precision and respect for the incredible forces at play. For our teams working across Texas and Oklahoma, this task is a controlled procedure, but it’s one where experience and the right tools are absolutely critical. It’s a job that can turn dangerous in a split second without them.

The entire adjustment comes down to one core principle: perfectly matching the spring’s stored energy to the exact weight of the garage door. Too little tension makes the door a dead weight. Too much, and it can fly open uncontrollably.

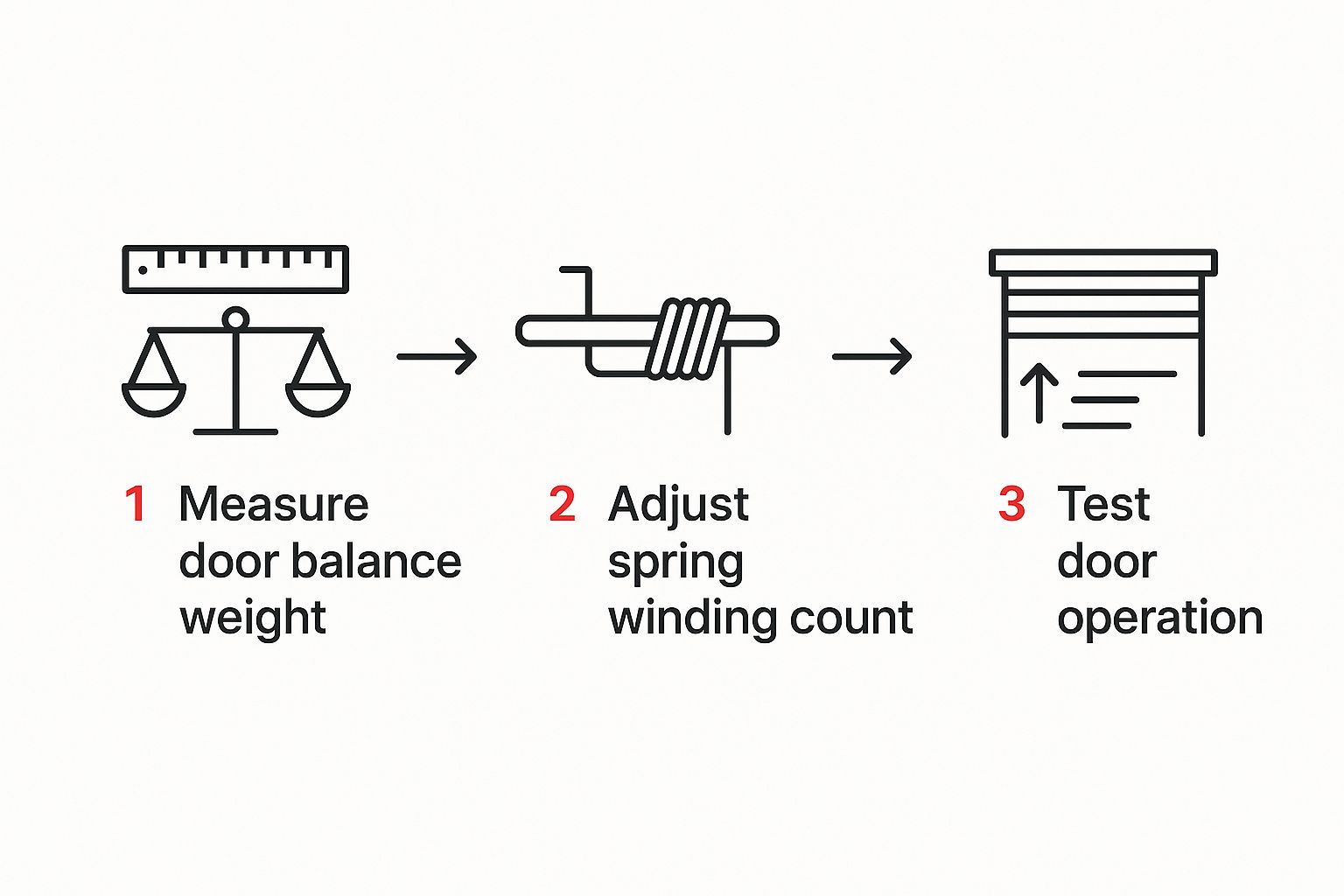

The infographic below outlines the three main phases of a professional adjustment.

As you can see, it’s a cycle of precise measurement, controlled adjustment, and meticulous testing. This is how we guarantee a safe and perfectly balanced door every time.

Securing the Door and Gathering Tools

Before a single screw is loosened, the first priority is to neutralize the system’s energy. We always start by closing the door completely, which takes most of the immediate tension off the springs.

From there, a technician will lock the door in place by clamping a pair of locking pliers or C-clamps firmly onto the vertical tracks, right above one of the bottom rollers. This is a non-negotiable safety step that prevents the door from shooting open while we work.

Next, it’s about having the right gear. This isn’t just any old tool from the truck; we’re talking about solid steel winding bars specifically made for the job. They have to be the correct diameter and length for the spring’s winding cone. Using screwdrivers, rebar, or anything else is a recipe for disaster and the number one cause of DIY injuries we see in the field.

The Unwinding and Winding Process

With the door secured, the technician begins the careful process of releasing the existing tension. They’ll insert one winding bar snugly into a hole on the winding cone, bracing it to take the full force of the spring. Only then do they loosen the set screws that anchor the spring to the central torsion tube.

Using two bars in a controlled “leapfrog” motion, they let the tension off one quarter-turn at a time. This methodical approach is the only way to safely handle the torque.

Once the spring is fully unwound, the real adjustment starts. A simple but effective pro-trick is to draw a line with chalk or a marker straight down the length of the unwound spring. This gives us a clear visual guide for counting the number of full rotations as we add tension back on.

On a typical 7-foot residential door, the starting point is usually 7.5 full rotations, which comes out to 30 quarter turns. But this is just a baseline. A door’s true weight, its height, and even the size of the cable drums all factor into the final calculation.

Winding the spring back up requires the same meticulous quarter-turn technique. Every turn adds a massive amount of energy, so maintaining a firm grip and complete control of the bars is essential. Once the calculated number of turns is applied, the technician tightens the set screws back down to the manufacturer’s specified torque, locking the spring’s new tension setting in place.

For heavy commercial doors at businesses from Lawton to Denison, this step is even more critical due to the extreme forces involved. If you have a commercial door that’s acting up, our commercial door repair services are geared for a fast response.

Final Balance Test and Fine-Tuning

With the tension set, the final phase is the balance test. We remove the clamps, disconnect the automatic opener, and manually lift the door to the halfway point. A perfectly balanced door will hang in the air, seemingly weightless.

- If the door drifts down, it’s still too heavy and needs a bit more tension.

- If the door slowly rises on its own, it has too much tension and needs to be backed off slightly.

The technician will then make tiny adjustments—usually just a quarter-turn at a time—until that perfect equilibrium is achieved. This critical step ensures your opener isn’t over-strained and that the door operates smoothly and safely for years. For any other issues, our comprehensive garage door repair services cover every aspect of your door’s health and safety.

Adjusting Extension Springs A Different Method

While torsion springs are the modern standard for most new garage doors, plenty of homes and businesses across Texas and Oklahoma still have the older extension spring systems. If you see long springs running parallel to the horizontal tracks on each side of your door, that’s what you’re working with.

These springs function completely differently from their torsion counterparts. Instead of winding up, they stretch and pull like giant, high-tension rubber bands to lift the door’s weight. Because they work independently on each side, getting the tension just right—and perfectly balanced—is everything.

An imbalance is one of the most common problems we encounter on service calls. When one spring pulls even slightly harder than the other, the door can start to jerk, shudder, or lift crookedly. This uneven movement doesn’t just make a lot of noise; it puts immense stress on the rollers, tracks, and even the door panels themselves, leading to premature wear and tear.

First Things First: Check for Safety Cables

Before you even think about making an adjustment, the absolute first thing you must do is look for safety cables. These are thin steel cables that run directly through the middle of each extension spring, anchored securely at both ends. Their job is critical.

Industry safety standards from organizations like the Door & Access Systems Manufacturers Association (DASMA) are clear: extension springs must have safety containment cables. When one of these springs breaks under immense tension, it can launch across your garage like a missile. I’ve seen the damage firsthand—it can easily go through a car door or drywall. The safety cable is the only thing that contains that explosive force.

If your springs don’t have safety cables threaded through them, stop what you are doing. Do not proceed. Installing them is a non-negotiable first step before any adjustment is made. The risk is simply too high.

How To Adjust The Tension

Unlike with torsion springs, you’ll be making adjustments with the garage door fully open. This is crucial because it relaxes the springs, removing the tension and making them much safer to handle. Once the door is all a way up and securely propped or locked in place, you can get to work.

The adjustment itself is a matter of repositioning where the spring connects to the track hanger. Look for the S-hook or pulley clip at the end of the spring cable; you should see it attached to a bracket with several holes or notches.

- Need more lift? If your door feels heavy or is difficult to open, you need to increase the tension. To do this, move the hook to a hole further away from the door, which will stretch the spring more when the door is closed.

- Door won’t stay down? If the door is hard to pull shut or wants to fly open, you need to decrease the tension. Move the hook to a hole closer to the door.

The key here is to make small, identical changes on both sides. Move the hook just one hole at a time, then carefully lower the door to test the balance. A perfectly balanced door should stay put when you open it halfway. If you’re running into issues or the door still doesn’t feel right, it’s best to call in the professionals. Our teams provide expert garage door repair services to get it done right and keep you safe.

Deciding Between Adjustment and Full Replacement

One of the most common questions we get from home and business owners across Texas and Oklahoma is whether a simple spring adjustment will do the trick, or if it’s time to replace the whole system. A quick tightening might seem like the easy, cheap fix, but often it’s just putting a band-aid on a bigger issue, especially with older springs. Making the right call here is about long-term safety and saving money down the road.

Sometimes, the spring makes the decision for you. If you see a clean break or a noticeable gap in the coils, replacement is the only safe option. Another major red flag, particularly in the humid climate we get here in Texoma, is heavy rust or corrosion. A rusty spring is a weak spring, period. You simply can’t trust it to hold the immense tension required to lift a heavy door.

When Metal Fatigue Sets In

The real debate starts when a spring just isn’t pulling its weight anymore. Over thousands of cycles of coiling and uncoiling, the steel experiences metal fatigue. This means it loses its structural integrity and can’t hold tension the way it did when it was new. You can’t see metal fatigue, but you can definitely feel it in how the door operates.

Think of it like an old rubber band. You can keep stretching it, but eventually, it gets brittle and just doesn’t have that snap-back anymore. Your garage door springs are no different. Sure, a technician can add more tension to an old, fatigued spring, but it’s going to lose that tension much, much faster than a brand-new one would.

A typical residential torsion spring is built to last for about 10,000 cycles—one cycle is one open and one close. As it gets close to that number, a simple tension adjustment becomes a very short-term patch on a worn-out part.

Age and Usage Are Your Guide

It’s normal for a new spring to need a little re-tensioning within the first few months, and maybe again after a few years. Losing tension is a natural process. But if your springs are pushing 7-10 years old, you’re likely throwing good money after bad by constantly adjusting them. You can find more real-world experiences on this topic by checking out discussions on how often springs need retensioning on Garage Journal.

At the end of the day, if a spring has lost a lot of tension because it’s old and worn out, replacing it is the smartest and safest move. A full garage door spring replacement isn’t just a repair; it’s a restoration. It brings your whole system back to factory-fresh condition, giving you a perfectly balanced, safe, and efficient door for years to come. It’s a smart investment to prevent a much more dangerous failure.

Common Questions About Garage Door Spring Tension

Even with the best instructions, you’re bound to have a few questions when it comes to something as specific as garage door spring tension. Let’s walk through some of the most common things we get asked by property owners here in Texas and Oklahoma.

How Many Turns Should a Torsion Spring Have?

This is the big one, but unfortunately, there’s no magic number that works for every door. The exact number of turns depends on several factors, like the height and weight of your door and the specific size of the cable drums.

As a general rule of thumb, a standard 7-foot residential door typically needs about 7.5 full rotations, which comes out to 30 quarter turns. But think of this as a starting point, not a final answer.

The only way to know for sure is to perform a balance test. A perfectly balanced door should stay put when you open it halfway. If it starts to drift down, you need more tension. If it wants to keep rising on its own, you’ve got too much. It’s this fine-tuning that really highlights why a pro should be handling the job.

Should I Adjust Only One Spring?

Absolutely not. This is a critical safety and performance point. Whether you have torsion or extension springs, they’re always installed in pairs for a reason: they’re designed to share the door’s weight equally. Because they do the same amount of work, they also wear out at roughly the same pace.

If one spring has lost its tension or snapped, you can bet the other one is right on its heels. When you only adjust or replace one spring, you throw the whole system out of balance. This puts a tremendous amount of strain on the older spring, the opener’s motor, and even the door panels themselves. For safety and the longevity of your system, always service springs as a pair.

An imbalanced door can cause a whole host of other problems. For instance, jerky or uneven movement can knock your safety sensors out of alignment, which is a major safety risk. You can read more about how to maintain your overhead garage door sensors to keep them working properly.

What Are Tension Issues on a Commercial Door?

The signs of a spring issue on a commercial door—like the big roll-up or sectional doors you see at a warehouse or auto body shop—are similar to residential doors, but the consequences are much bigger. Because these doors are so massive, the symptoms are amplified.

Look out for these red flags:

- The manual chain hoist is a real workout. The door feels incredibly heavy and difficult to lift.

- The door won’t stay open. After you open it, it slowly starts to drift back down.

- The motor sounds like it’s in pain. You might hear loud groaning, skipping, or straining sounds from the opener.

- The door rolls up crookedly. You might notice it “barreling” or looking lopsided as it opens.

With the massive forces at play in commercial spring systems, any of these signs should prompt an immediate call to a certified technician. Attempting a DIY garage door spring tension adjustment on one of these doors is extremely dangerous.

At Overhead Door Co. of Tex-Oma, our philosophy is simple: do it right, and do it safely. If you notice any signs that your garage door’s spring tension is off, don’t leave it to chance. Contact our expert team for professional, reliable service across Texas and Oklahoma by visiting us at https://ohdctexoma.com.