At the bottom of your garage door opening, you’ll find a pair of small photo-electric eyes. These little devices are the unsung heroes of your garage, creating an invisible infrared beam that spans the entrance. If anything breaks that beam while the door is closing, the system instantly tells the door to reverse course, preventing what could be a serious accident.

This isn't just a convenient feature; it's a critical safety system mandated by federal law on every modern residential and commercial garage door. According to the U.S. Consumer Product Safety Commission (CPSC), this and other safety features have dramatically reduced injuries, but proper maintenance remains essential.

Your Garage Door's Unseen Safety Net

Think of your safety sensors as an invisible tripwire, constantly standing guard. This system is your first line of defense against the immense force of a closing garage door, which can exert over 150 pounds of pressure. A descending door without working sensors is a major hazard to children, pets, and vehicles.

For homeowners across Texas and Oklahoma, these sensors are an absolute must-have for keeping the family safe. For business owners, whether you're running a warehouse in Shawnee or an auto shop in Abilene, they are a fundamental part of workplace safety, required under OSHA standards to prevent accidents and keep your operation running smoothly.

Why These Little Sensors Are a Big Deal

The role of overhead garage door sensors goes far beyond simple convenience; it’s rooted in both practical safety and legal necessity.

- Preventing Accidents: The CPSC estimates that properly functioning sensors prevent thousands of serious injuries each year. By detecting an obstruction in a split second, they stop a potential tragedy before it happens.

- Protecting Your Property: A sensor can be the difference between a close call and a crushed car hood. It prevents costly damage to vehicles and equipment, saving you an expensive insurance claim. An average garage door repair can cost several hundred dollars, making the sensor an invaluable investment.

- Staying Compliant: It’s the law. Since 1993, federal regulation UL 325 has required all garage door openers made and sold in the United States to include a safety reversing feature like photo-eye sensors.

A working sensor system isn’t just an accessory—it's a core safety requirement. Keeping these devices in good working order is a crucial responsibility for any property owner in Texas and Oklahoma, protecting both people and property from harm.

This guide will walk you through exactly how these sensors work, the standards they must meet, and what you can do to keep them functioning perfectly. We’ll cover everything from the basics to routine maintenance, giving you the confidence to maintain a safe and reliable garage door system.

For a deeper dive into overall safety practices, our articles on garage door safety provide more essential tips for property owners.

How Photo-Eye Sensors Prevent Accidents

Ever seen a spy movie where the hero has to navigate a web of laser beams? Break one, and the alarm goes off. That’s almost exactly how your garage door's safety sensors work, just on a much simpler and more practical scale. It's a brilliantly effective system designed purely for safety.

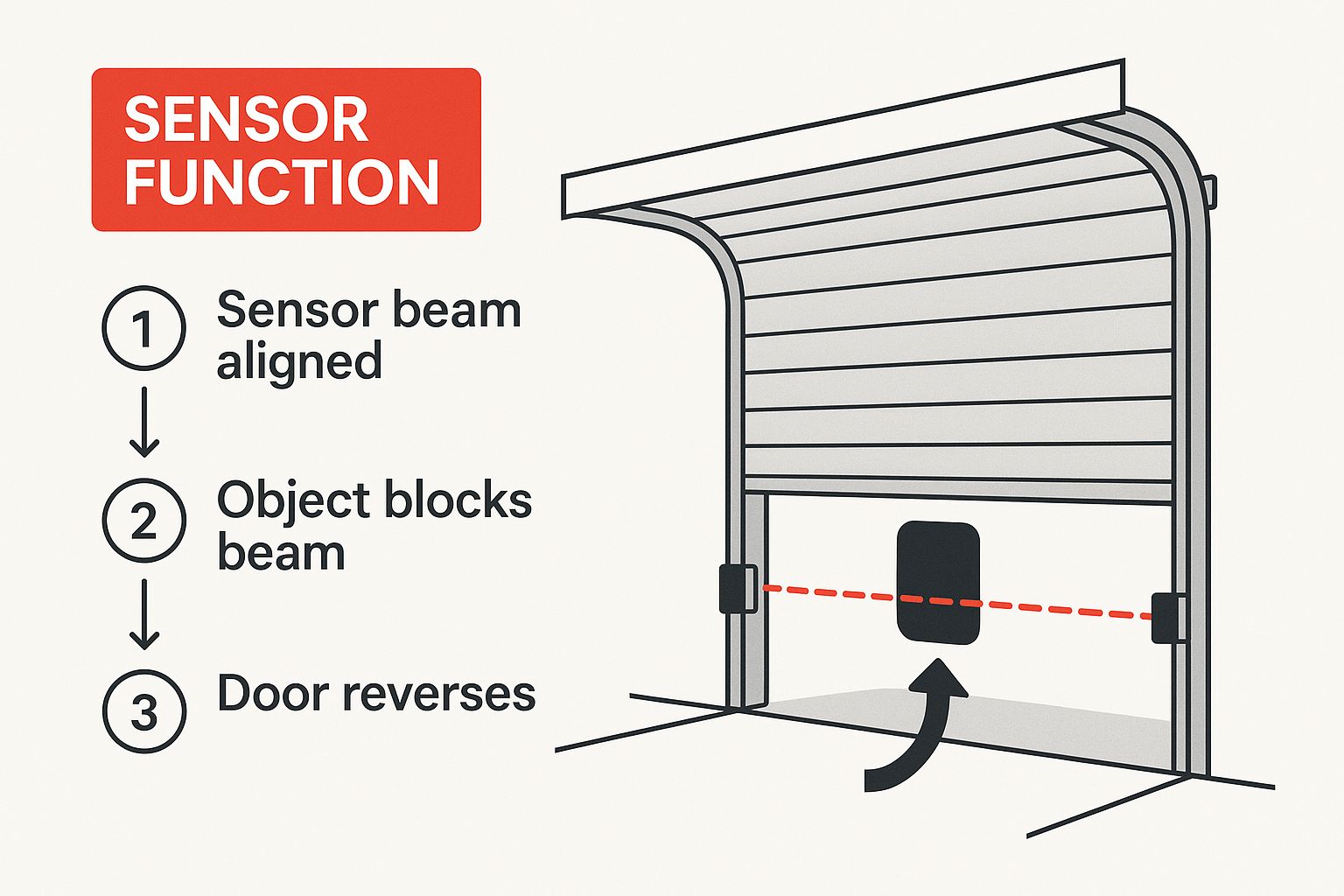

The setup involves two small boxes on either side of your garage door opening. One is the transmitter, which shoots a focused, invisible beam of infrared light across the opening. The other box is the receiver, patiently waiting to catch that beam. As long as the receiver can "see" the beam, it gives the garage door opener the all-clear signal to close.

The moment anything—a stray toy, your pet, or even your foot—crosses that path, the beam is broken. Instantly, the receiver tells the opener's main logic board, "Stop! Something's in the way!" The door immediately reverses course and heads back up. It all happens in the blink of an eye, preventing a potential accident.

The Reason They’re Mounted So Low

You’ve probably noticed that these sensors are always installed just a few inches off the garage floor. That’s not just a random placement; it’s a strict safety requirement governed by the UL 325 safety standards. The rule is clear: sensors must be mounted no more than six inches from the ground.

This specific height is crucial. It ensures the beam is low enough to detect even small children or pets that might wander under the closing door. If the sensors were mounted any higher, they could easily miss a toddler crawling or a pet lying down, creating a dangerous blind spot right where you need protection the most.

This image perfectly illustrates how that low-slung beam creates an essential safety net.

As you can see, positioning the beam near the floor provides a comprehensive protective barrier right at the point of greatest risk, guaranteeing that an obstruction is detected long before the heavy door gets anywhere near it.

Safety as a Driving Force in the Market

The widespread adoption of this technology isn't just about convenience; it's a massive driver of market growth. The global garage door service market is already valued at $4.78 billion and is expected to climb to $7.16 billion by 2032. Much of that growth comes from the demand for safer, more reliable automated systems.

For businesses in Texas and Oklahoma, a malfunctioning sensor is more than an inconvenience—it can shut down loading docks, halt logistics, and cause costly delays. It underscores just how vital these small devices are in our daily lives and commerce.

In the end, this simple "beam-break" technology is arguably the single most important safety feature on your garage door. It's responsible for preventing countless injuries and saving property owners from expensive damage year after year.

While we're focused on garage doors here, the same core principles apply to other automated entry systems. For a broader perspective, it's worth understanding automatic gate safety features to see how similar technologies keep those systems safe, too.

Staying Compliant with Safety Codes in Texas and Oklahoma

Having working overhead garage door sensors isn't just a nice-to-have feature; it's a legal must-have for property owners in Texas and Oklahoma. This isn't a suggestion—it's your primary safeguard against accidents, property damage, and serious legal liability. At the heart of it all is a federal standard known as UL 325.

Back in 1993, a major shift happened. The UL 325 standard made it mandatory for all professionally installed residential garage door openers to include a non-contact safety reversing system. This was a direct response to tragic accidents, and it completely changed how the industry approached safety. The photo-eye sensors we're familiar with today are the direct result of that rule.

What Is the UL 325 Standard?

Think of UL 325 as the official safety playbook for garage doors. It lays out a few crystal-clear rules that manufacturers and installers must follow, with no exceptions.

- Non-Contact Reversal: The system must detect an obstruction and reverse the door without physically touching it.

- Low-Down Placement: The sensors must be installed no more than six inches off the ground. This specific height is crucial for detecting small children or pets that might wander into the door's path.

- Constant Monitoring: The opener’s logic board constantly checks to ensure the sensors are powered up and communicating. If it detects a problem (like a cut wire or misalignment), it will prevent the door from closing remotely, often flashing the opener lights as a warning.

Following these rules establishes a fundamental safety net for every modern garage door. An installation that cuts corners here doesn't just put people in danger—it could also create major problems with your homeowner's or business insurance if an accident were to happen.

Commercial Doors: Meeting OSHA and NFPA Rules

For businesses in Texas and Oklahoma, the stakes are even higher. Places like warehouses, auto repair shops, and facilities with loading docks have another layer of rules to follow from the Occupational Safety and Health Administration (OSHA).

In a workplace, a garage door is considered machinery, and OSHA's General Duty Clause (Section 5(a)(1)) requires employers to provide a workplace free from recognized hazards. A commercial door with faulty or missing sensors is a direct violation that can result in hefty fines, work stoppages, and a legal nightmare.

On top of that, some buildings also have to meet standards from the National Fire Protection Association (NFPA), such as NFPA 80 for fire-rated doors. These doors must close in an emergency but must still be able to reverse if something is in the way. If you're navigating a commercial setup, our team has deep experience with commercial door installation and can make sure your facility is up to code.

The industry's sharp focus on these safety standards is a big part of why the market keeps growing. Projections show the North American overhead door market is set to hit around $1.48 billion by 2025, and a huge piece of that growth is tied directly to better sensor technology. If you want to see the numbers behind this trend, you can explore the full overhead door market report. It’s clear that investing in compliant sensor tech isn't just about ticking a box—it's about embracing the industry standard for keeping people safe.

Troubleshooting Common Sensor Problems

It’s one of the most frustrating things that can happen with a garage door: you hit the button, and it starts to close, only to immediately reverse and go back up. When your door starts acting possessed, the overhead garage door sensors are almost always the culprits.

The good news? You can often figure out what’s wrong and fix it yourself in just a few minutes. The key is to learn how to "read" the little LED lights on the sensors themselves.

Decoding the LED Lights

Think of the LEDs as a simple diagnostic system. One sensor, the transmitter, sends out the infrared beam and usually has a solid amber or orange light. This just tells you it has power.

The other sensor, the receiver, is the one you really need to watch. It should have a solid green light. A steady green light means it’s catching the beam perfectly from the transmitter, and everything is working as it should. If that green light is flickering, dim, or completely off, the system is telling you the beam is broken.

Here’s a quick breakdown of what the lights mean:

- Solid Green Light (Receiver): This is the goal. It means the sensors are aligned and communicating. If your door still won't close, the problem is likely somewhere else, perhaps with the opener's internal wiring or logic board.

- Flickering or Off Green Light (Receiver): This is by far the most common issue. The receiver isn't "seeing" the transmitter's beam. The cause is usually something simple: misalignment, a physical obstruction, or just a dirty lens.

- No Lights on Either Sensor: This points straight to a power problem. The sensors aren't getting electricity from the opener unit. You could be dealing with a cut wire or a more significant issue inside the opener itself.

Pro Tip: Before you start messing with alignment or wiring, just do a quick visual check. I’ve seen spiderwebs, stray leaves, and caked-on dust completely block the beam. A quick wipe with a soft, dry cloth is often all it takes to get things working again.

A Quick Troubleshooting Guide

When your sensor lights aren't behaving, it can be tough to remember what to do next. This table breaks down the most common symptoms and gives you a clear path forward, from simple DIY fixes to knowing when it's time to call in the pros.

| Symptom | Potential Cause | DIY Solution | When to Call a Pro |

|---|---|---|---|

| Blinking Green Light | The sensors are slightly out of alignment or there's a minor obstruction. | Check for small items (leaves, webs) in the beam's path. Loosen the sensor bracket and gently adjust it until the green light is solid. | If you can't get the light to stay solid no matter how you adjust it. |

| No Green Light | The sensors are completely misaligned, blocked by a large object, or the lens is very dirty. | First, clear any objects from between the sensors. Thoroughly clean both lenses. Check the alignment by trying to sight them like a scope. | If cleaning and basic alignment don't work, the sensor may have failed. |

| No Light on Either Sensor | A power issue. A wire is likely disconnected, cut, or damaged. | Visually inspect the wires from the sensors all the way to the motor unit for any obvious damage. Check the connections at the back of the opener. | If you see frayed wires, signs of pest damage, or can't find the issue. |

| Sensors Look Fine, Door Still Won't Close | The problem might be with the opener's logic board, internal wiring, or travel limit settings. | You can try a power cycle (unplug the opener for 60 seconds and plug it back in) to reset the logic board. | If a power cycle doesn't help, the issue is internal and requires a technician. |

Troubleshooting is a process of elimination. Start with the easiest fix and work your way up.

Step-by-Step DIY Fixes

Once you have a good idea of the cause, you can try these simple solutions. Always disconnect the power to your garage door opener before touching any wires.

- Check for Obstructions: Seriously, check again. It's amazing what can get in the way. Shovels, bikes, trash cans, and storage bins are common culprits that get bumped into the beam's path.

- Clean the Sensor Lenses: Garages in Texas and Oklahoma are dusty places. That grime builds up on the photo-eye lenses and can easily block the invisible beam. A microfiber cloth is perfect for the job.

- Realign the Sensors: This is the classic fix for a flickering green light. Just loosen the wingnut on the sensor's bracket and carefully pivot the receiver. You'll see the green light come on when you hit the sweet spot—tighten the wingnut down once it's solid.

- Inspect the Wiring: Take a look at the thin wires running from both sensors up to the motor unit. Look for any loose connections, staples that have pierced the wire, or signs of damage from pests.

While you can solve most sensor problems yourself, some issues point to a deeper failure. If you've gone through these steps and the door still misbehaves, or if you find damaged electrical wires, it's best to call for a professional. For a broader look at what can go wrong, explore our guide covering other common garage door issues that property owners often face.

Proactive Maintenance for Long-Term Reliability

Don't wait for your garage door to break down. That's a recipe for inconvenient, and often expensive, emergency repairs. The smart approach is proactive maintenance, treating your overhead garage door sensors like any other essential piece of equipment to keep them working flawlessly all year. Just a few minutes of preventative care every few months can save you the headache of being trapped inside—or outside—your garage.

This isn't just about convenience; it's about embracing the safety technology that defines the modern garage door. The global market for these systems was valued at $7.27 billion in 2024 and is expected to climb to $9.83 billion by 2029. Why the growth? People are demanding safer, smarter doors, and sensors are the heart of that reliability. You can read more about these market trends to see just how critical these components have become.

Your Essential Maintenance Checklist

Checking your sensors regularly is something any homeowner or facility manager can handle. These simple inspections stop small issues from snowballing into complete failures.

- Clean the Photo-Eye Lenses: Dust, dirt, and spiderwebs are the number one cause of sensor problems. Just wipe both lenses with a soft, dry microfiber cloth once a month to keep the beam's path clear.

- Perform a Quick Alignment Test: Grab a cardboard box and place it on the ground where the door comes down. When you hit the close button, the door should touch the box and immediately go back up. If it crushes the box or doesn't reverse, your sensors need a professional look.

- Inspect the Wiring: Take a moment to trace the thin wires from each sensor all the way back to the motor unit. Keep an eye out for any damage—frayed spots, pinched sections, or chew marks from critters can all cause frustrating connection issues.

- Clear the Surrounding Area: It’s easy for shovels, brooms, or storage bins to get leaned against the wall and accidentally block a sensor. Make sure the area around both photo-eyes is always clear.

Tips for Texas and Oklahoma Properties

Our local climate throws a few curveballs. For a dusty commercial warehouse in Texas, for example, cleaning the sensor lenses more often is a must to prevent operational hiccups. Over in the more humid parts of Oklahoma, moisture can sometimes take a toll on electronic components, making those wiring inspections even more important.

A proactive maintenance routine is your best strategy for extending the life of your overhead garage door sensors. It transforms them from a potential point of failure into a consistently reliable safety feature.

By following these simple steps, you can catch small problems before they become major headaches. For more in-depth guidance, check out our resources on garage door maintenance.

Frequently Asked Questions About Garage Door Sensors

Even after you get the hang of how garage door sensors work, you're bound to have some practical questions. We get calls from homeowners across Texas and Oklahoma all the time with these very same questions, so let's clear up some of the most common ones.

Can I Just Bypass My Garage Door Sensors?

You’ll find a way to do it, but you absolutely shouldn't. Most garage door openers let you override the sensors by pressing and holding the wall button until the door is completely closed. This is strictly meant as a temporary workaround to get your property secured until a technician can make a proper repair.

Permanently disabling or bypassing your sensors is a massive safety gamble. It’s also a direct violation of federal UL 325 safety standards, which means you could be held liable for any accidents, injuries, or property damage that happens as a result. It's a dangerous shortcut that strips away the single most critical safety feature on your entire system.

What's the Typical Cost to Replace Sensors in Texas and Oklahoma?

For a professional to come out and replace your garage door sensors, you can generally expect the cost to be somewhere between $150 and $250. That price usually covers everything—the new pair of sensors, the labor for installation, wiring, alignment, and a final test to make sure it's all working perfectly.

A few things can nudge that price up or down:

- Brand of Opener: Sensors from major brands can sometimes cost a bit more than universal replacement kits.

- Wiring Condition: If the existing wiring is frayed, corroded, or damaged, it'll add a little more time and material to the job.

- Accessibility: If the opener unit or wiring is in a tight, hard-to-reach spot, it might add a bit to the labor cost.

While you might find a sensor kit online for only $30-$50, having a pro handle it ensures the job is done right. They'll make sure it's wired correctly and perfectly aligned to meet safety codes, which buys you invaluable peace of mind.

Are All Garage Door Sensors Interchangeable?

No, they really aren't. While you'll see "universal" sensor kits on the market, there's no guarantee they will play nicely with every make and model of garage door opener. The smartest and safest move is to stick with sensors made by your opener's manufacturer, whether that's LiftMaster, Chamberlain, Genie, or another brand.

Using mismatched sensors is a recipe for trouble. It can cause compatibility headaches, unreliable performance, or—worst-case scenario—a total failure of the safety system. Your opener's logic board is designed to "talk" to a specific type of sensor, and the wrong one can throw the whole system off.

When it's time for a replacement, your best bet is to find your opener's model number and look for the exact part. If you’re not sure, calling a professional is the surest way to get the right components for a safe and solid repair. Our team can handle any garage door repair services and make sure your system has the correct parts.

How Long Do Garage Door Sensors Last?

On average, you can expect a good 10 to 15 years of service from your garage door sensors. Of course, like any piece of electronics, their actual lifespan comes down to a few factors, like how often the door is used, the environment they live in, and whether they're maintained.

Sensors in a dusty Texas workshop or a humid area might fail sooner if they aren't cleaned off once in a while. Physical damage is another big one—we see sensors that have been bumped by cars, lawnmowers, or stray tools all the time. A little bit of regular cleaning and a quick visual inspection can go a long way in making them last.

And when the time comes for a complete upgrade, our experts can walk you through all the modern residential garage door installation options available today.

For expert help with your garage door sensors or any other part of your system, trust the pros at Overhead Door Co. of Tex-Oma. We provide reliable installation, maintenance, and repair services to keep your doors running safely. Contact us today to schedule a service call in Texas or Oklahoma.