Ignoring your overhead door is more than a minor oversight—it's a potential threat to your business operations and home security. Treating overhead door maintenance as a strategic, data-backed investment, rather than a chore, is the key to preventing costly downtime and ensuring reliable performance day after day.

Why Consistent Overhead Door Maintenance Matters

Imagine a distribution center in the Texas heat of mid-July. A critical loading dock door grinds to a halt, trapping a truck and halting shipments. According to industry data, unplanned downtime can cost a business an average of $5,600 per minute. For that distribution center, a simple mechanical failure just turned into a five-figure loss.

This isn't just a commercial problem. At home, a poorly maintained garage door can become a safety hazard. The solution is shifting from a reactive, high-cost repair model to a proactive, preventive strategy that protects your assets and your people.

The High Cost of Neglect

Postponing routine upkeep is a gamble with significant financial and safety consequences. Industry data supports this: repair and maintenance services are projected to account for 46.2% of the nearly $4.8 billion global garage door service market by 2025. This staggering figure highlights how many property owners wait for a breakdown before seeking professional help.

When you delay service, you invite predictable problems:

- Operational Disruption: For any business in Texas or Oklahoma, a non-functional bay door directly translates to lost revenue and supply chain bottlenecks.

- Safety Risks: A failing door is a physical hazard. For commercial properties, this can lead to serious OSHA violations. Per OSHA standard 1910.212(a)(1), all machines must have adequate guarding to protect operators from hazards. A malfunctioning door can easily violate this principle.

- Accelerated Wear and Tear: Our regional climate is unforgiving. Intense UV radiation degrades weather seals, while dust and grit infiltrate mechanical parts, accelerating their failure rate.

A proactive maintenance schedule isn't an expense; it's an investment in reliability, safety, and long-term savings. Identifying a worn roller or a misaligned track today can prevent a catastrophic system failure tomorrow.

To create a targeted maintenance plan, it's essential to understand the different priorities for residential and commercial properties.

Maintenance Priorities for Overhead Doors

This table breaks down the critical inspection points, highlighting the different concerns for a home garage versus a commercial loading dock.

| Component | Residential Focus (Home Safety & Security) | Commercial Focus (OSHA Compliance & Uptime) |

|---|---|---|

| Springs | Balancing, rust prevention, and safe tension levels. A broken spring can cause the door to slam shut. | Cycle count tracking, stress fracture inspection, and immediate replacement of worn components to avoid downtime. |

| Cables & Pulleys | Checking for fraying or rust. A snapped cable is a major safety risk. | Ensuring proper tension and alignment to handle high-volume use and prevent operational stoppages. |

| Rollers & Tracks | Cleaning tracks of debris and lubricating rollers for smooth, quiet operation. | Inspecting for bent tracks or worn-out rollers that could derail the door under heavy load. |

| Safety Sensors | Verifying alignment and functionality of photo-eye sensors to protect people and pets. | Testing all safety mechanisms, including reversing edges and timers, to meet federal safety standards like UL 325. |

| Weather Seals | Inspecting for cracks or damage to keep out pests, water, and extreme temperatures. | Ensuring seals are intact to maintain climate control, reduce energy costs, and protect inventory. |

While the core components are the same, the stakes and standards are significantly higher in a commercial setting, where a failure impacts safety, compliance, and profitability.

For those managing multiple properties and looking to stay ahead of the curve, exploring advanced solutions like AI property maintenance strategies can provide a fresh perspective on asset management. But at the end of the day, it all comes back to consistent, hands-on care.

Whether you're in Lawton or elsewhere in Texoma, recognizing the need for professional service is the first step. Our team offers comprehensive garage door service in Lawton to keep your doors—and your day—running smoothly.

Your Essential Sensory Inspection Checklist

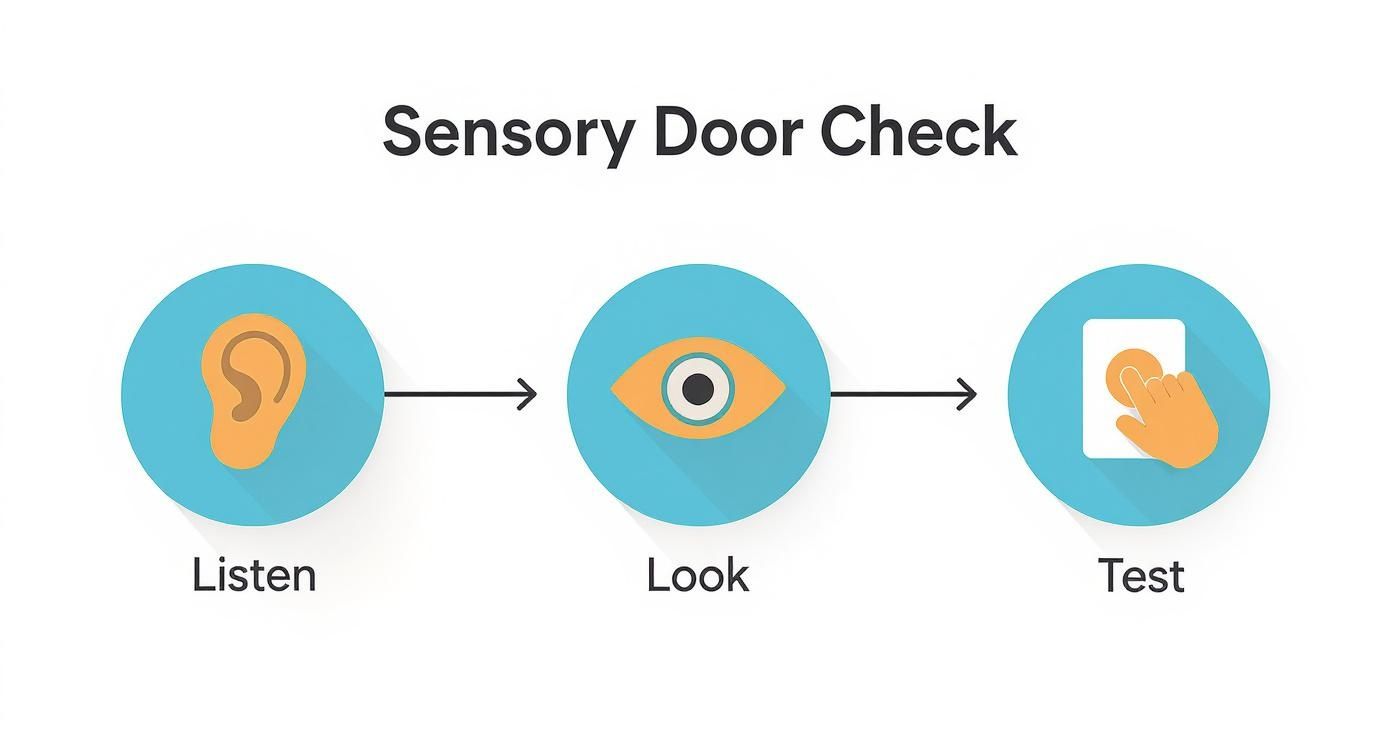

You don’t need specialized equipment to detect the early warning signs of an overhead door problem. Your own eyes and ears are two of the most effective diagnostic tools available. Integrating a regular sensory inspection into your property maintenance routine is the cornerstone of a solid overhead door maintenance plan, helping you spot trouble before it escalates into an expensive and dangerous emergency.

Think of it as a quick monthly health checkup. Taking just a few minutes to observe your door in action can reveal subtle changes that indicate underlying issues.

What to Look For: The Visual Cues

First, stand back and watch the door complete a full cycle—all the way up and all the way down. You're looking for smooth, even movement, not a jerky, hesitant, or lopsided motion. If the door shudders or seems to struggle, it’s a clear sign that something is amiss, often pointing to incorrect spring tension or a track alignment issue.

After observing the full cycle, get closer and inspect the key hardware:

- Cables: Look for any signs of fraying, particularly near the bottom brackets. Even a few broken strands are a serious red flag; the cable's integrity is compromised and it could snap without warning.

- Springs: Scan the torsion springs for visible rust or, more critically, any gaps between the coils. A noticeable gap indicates a broken spring—an extremely dangerous situation that requires immediate professional service.

- Rollers: Check the rollers for cracks, chips, or excessive wear. Worn-out rollers are a common cause of a door jamming or binding in its tracks.

- Tracks: Visually inspect the vertical and horizontal tracks for bends, dents, or debris buildup. In Texas and Oklahoma, fine dust can quickly pack into the tracks, creating friction that puts significant strain on the opener motor.

Actionable Tip: Perform a door balance test. With the door closed, disconnect the opener (usually by pulling the red emergency release cord) and manually lift the door to about waist height. It should stay in place. If it slams down or flies open, the springs are dangerously out of balance and require professional adjustment.

What to Listen For: The Audible Warnings

The sounds your door makes are just as informative as its visual cues. A well-maintained door should operate relatively quietly. New or unusual noises are clear indicators of a problem.

- A sudden, loud pop or bang is the classic sound of a broken torsion spring. It’s an unmistakable noise that means your door is inoperable and unsafe.

- Grinding or scraping sounds nearly always point to worn-out rollers or debris in the tracks, forcing metal-on-metal contact.

- A high-pitched squealing or groaning is typically a sign that metal parts like hinges and roller stems require lubrication.

This proactive approach is more important than ever. North America is a leader in the global overhead doors market, accounting for 36% of 2024 revenue, a figure driven by strict safety codes and regional building requirements. Regular maintenance ensures your door continues to meet these high standards. You can discover more insights on regional market trends and see how they impact local requirements.

If your inspection reveals significant wear, fraying cables, or alarming sounds, take immediate action. For a business, professional commercial door repair is critical for maintaining safety and preventing downtime. Homeowners should also call a qualified technician promptly to prevent a small problem from becoming a major failure.

A Pro's Guide to Lubrication and Adjustments

With your inspection complete, it’s time for the single most effective DIY maintenance task: proper lubrication. This simple step can dramatically quiet a noisy door and reduce wear and tear on its moving parts.

A common mistake is using a penetrating oil like WD-40. This product is a solvent and degreaser, not a long-term lubricant. It will strip away existing grease and attract dust, creating a gummy residue that worsens the problem. Instead, use a dedicated garage door lubricant, which is typically a lithium- or silicone-based spray.

How to Lubricate Like an Expert

The goal is to apply a light, clean coat to every moving metal part to reduce friction.

Target these specific spots:

- Hinges: Apply a quick spray to each hinge pivot point.

- Rollers: Aim for the ball bearings inside the rollers and the stems. Crucial Tip: Never spray lubricant directly into the tracks. You want the rollers to roll, not slide. Grease in the tracks will cause them to slip, leading to premature wear.

- Springs: A light mist across the torsion springs helps prevent rust and corrosion, reducing friction and noise.

- Bearings: Lubricate the bearings at each end of the torsion bar and in the center plate above the door.

This simple sensory check process is what helps you identify the problem spots before you even pick up the lubricant.

When you listen, look, and test first, you’ll know exactly which squeaky hinge or grinding roller needs your attention.

Simple Mechanical Tweaks You Can Safely Make

Lubrication is one part of the equation. The constant vibration from door operation can loosen nuts and bolts over time.

With the door fully closed, use a socket wrench to go over all hardware. Gently snug up any loose nuts and bolts on the hinges and roller brackets. The key is to snug them—do not overtighten. Cranking down too hard can strip the bolts or damage the door panel.

STOP: A Critical Safety Warning

Certain components of a garage door system must never be adjusted by untrained individuals. The high-tension torsion springs and the lift cables (especially where they connect to the red-painted bottom brackets) are under extreme force. Attempting to adjust or remove them can result in catastrophic failure, causing serious injury or death. This work should be performed exclusively by trained professionals.

These DIY steps are highly effective, but a truly reliable system includes modern components. Considering upgrades like advanced garage door accessories can enhance both the safety and convenience of your home or business.

How to Test Your Door's Safety Systems

After inspecting and lubricating your door, the next critical step is to test its safety features. These systems are not optional; they are legally mandated protections designed to prevent serious accidents and property damage.

Skipping these simple monthly checks is an unnecessary risk. These tests are straightforward and ensure your door opener complies with the UL 325 standard that all modern systems must meet.

Verifying the Auto-Reverse Mechanism

The primary safety feature is the auto-reverse function. It's designed to stop and reverse the door if it encounters an obstruction while closing.

Here is the industry-standard test:

- Place a 2×4 board flat on the ground in the door's path.

- Activate the door to close.

- The moment the door's bottom edge contacts the board, it must immediately reverse direction and open fully.

If the door continues to push down on the board, stop it immediately. A door that fails this test has excessive force settings and is a significant hazard. It should not be used until adjusted by a professional.

Checking the Photoelectric Sensors

The photoelectric sensors, or "safety eyes," located near the bottom of the tracks create an invisible infrared beam across the opening. If anything breaks this beam while the door is closing, the opener must reverse course instantly.

To test this system:

- Start the door closing.

- Carefully wave a broom handle or your foot through the beam's path.

- The door should immediately stop and reverse to the fully open position.

If the door continues to close, check the sensors. Most have small LED indicator lights. If the lights are off or flickering, the sensors may be misaligned or faulty.

Key Insight: A faulty safety system is a major liability. The global overhead door market is projected to hit $5.4 billion by 2025, with a heavy emphasis on advanced safety and automation. Regular testing is the only way to ensure these critical features function correctly. You can learn more about the expanding overhead door market and its focus on safety standards.

For our commercial clients in Texas and Oklahoma, safety standards are even more stringent. Fire-rated doors, for example, must comply with NFPA 80 standards, which mandate annual "drop tests" to verify they close automatically during a fire alarm. This is a specialized test that must be performed and documented by a certified technician.

If you find any issue during these tests, it’s time to call for professional assistance. Promptly addressing safety system failures is a non-negotiable part of responsible garage door repair and ownership.

Adapting Maintenance for Texas and Oklahoma Weather

Living in Texas or Oklahoma means dealing with a climate of extremes. The relentless summer heat and sudden winter freezes put immense stress on building exteriors, and your overhead door is on the front line. A generic maintenance checklist is insufficient here; you need a strategy for overhead door maintenance that directly addresses our region's unique weather challenges.

Ignoring these local factors is a recipe for premature failure. A door that performs well in a milder climate can quickly degrade when exposed to intense UV radiation and drastic temperature swings.

Battling the Summer Heat

The triple-digit temperatures common in our summers are a direct assault on your door. The combination of intense heat and UV radiation can degrade critical components, leading to energy loss and sudden mechanical failures.

Your summer maintenance focus should be on preservation and efficiency:

- Inspect the Weatherstripping: Examine the vinyl or rubber seals around the perimeter of your door. Look for cracking, brittleness, or warping. A compromised seal allows super-heated air to infiltrate your space, driving up cooling costs and providing entry for pests.

- Protect Sensitive Electronics: The circuit board in your door opener is vulnerable to extreme heat. In a poorly ventilated garage or warehouse, soaring ambient temperatures can shorten the lifespan of these electronics, causing intermittent and difficult-to-diagnose failures.

A study by the Lawrence Berkeley National Laboratory found that a poorly sealed garage can account for up to 30% of a home's total air leakage. In a Texas summer, that translates directly to higher energy bills from an overworked HVAC system.

Preparing for Winter Cold Snaps

While our winters are often mild, sudden cold snaps and ice storms present their own set of maintenance challenges. The priority shifts to preventing components from seizing and ensuring the door remains a solid thermal barrier.

When temperatures drop, metal contracts and lubricants can thicken, forcing the opener motor to work harder. Proactive maintenance is the difference between a smoothly operating door and being frozen out of your building. Using a high-quality, all-weather lubricant is critical.

A well-maintained and properly sealed door is essential for keeping your building secure and energy-efficient during a January cold front. This seasonal approach is a smart strategy for any property owner. If you prefer professional assurance, scheduling a tune-up before extreme weather hits is a wise investment. You can learn more about what that entails with a dedicated residential garage door service to ensure every component is prepared for what our climate throws at it.

Got Questions About Door Maintenance? We’ve Got Answers.

We’ve covered the core elements of keeping your overhead door in top condition, but you might still have questions. Our technicians, working on everything from commercial sites in Denison to residential homes in Abilene, hear the same inquiries from property owners across Texoma.

Here are the straightforward answers to the most frequently asked questions.

How Often Should I Call a Pro for Service?

For a typical residential garage door, a professional inspection and tune-up once a year is the industry-recommended benchmark. This annual service is the best way to catch minor issues before they become major expenses and to verify that all safety systems are functioning correctly.

Commercial doors are evaluated based on usage, or "cycle count." A high-traffic door at a logistics facility may require quarterly professional service. A low-usage storage unit door might be fine with an annual check. However, at a minimum, every commercial door should be professionally serviced annually to ensure safety and operational reliability.

What’s a Real Emergency vs. a Minor Problem?

Some door issues are more than an inconvenience—they are urgent safety hazards that require immediate professional attention. Stop using the door and call a technician if you encounter any of the following:

- A Loud "Bang" Followed by a Stuck Door: This is almost certainly a broken torsion spring. A visual inspection will likely reveal a gap in the spring coils above the door.

- Frayed or Snapped Cables: The lift cables manage the door's weight. If one is broken or fraying, the door is unstable and extremely dangerous.

- The Door is Off-Kilter or Off Its Tracks: If any rollers have come out of the guide tracks, the door could fall without warning.

Actionable Tip: Never attempt to operate a door with a broken spring or cable. These doors can weigh several hundred pounds and can fall with crushing force. This is a serious hazard that requires immediate professional intervention.

Is It Better to Repair My Old Door or Just Replace It?

This decision typically hinges on three factors: safety, cost-effectiveness, and energy efficiency.

First, safety. If your door is an older model that predates modern photoelectric safety sensors (mandated by law since 1993), replacement is the wisest choice for the safety of your family or employees.

Next, analyze the cost. If you are frequently paying for repairs, the cumulative cost can quickly approach that of a new, reliable system. A new door often makes better long-term financial sense.

Finally, consider energy efficiency. An old, uninsulated door can significantly impact your heating and cooling bills. A modern insulated door provides a much better thermal barrier, which can lead to tangible savings on utility costs in the Texas and Oklahoma climate.

Can't I Just Replace a Broken Spring Myself?

In one word: No. We cannot overstate this. Attempting to replace a torsion spring is one of the most dangerous DIY projects a property owner can undertake.

Torsion springs are wound under extreme tension, storing an immense amount of mechanical energy. An uncontrolled release can turn the spring or winding bars into high-velocity projectiles, causing severe injury or death. This job requires specialized tools and a deep understanding of the physics involved. Please leave it to a trained and insured professional. Your safety is not worth the risk.

Whether you have a quick question or need a complex commercial repair, the expert technicians at Overhead Door Co. of Tex-Oma are here to help. We keep doors running safely and reliably all across Texas and Oklahoma. Schedule your maintenance service today!